|

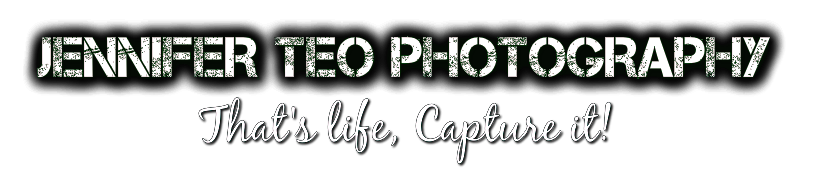

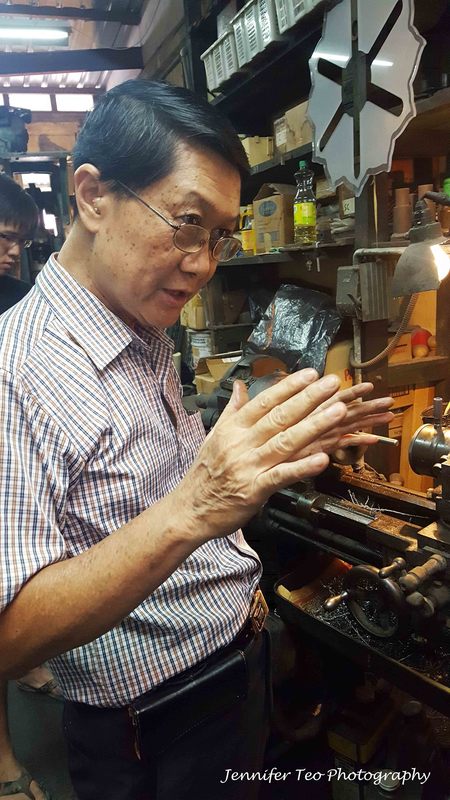

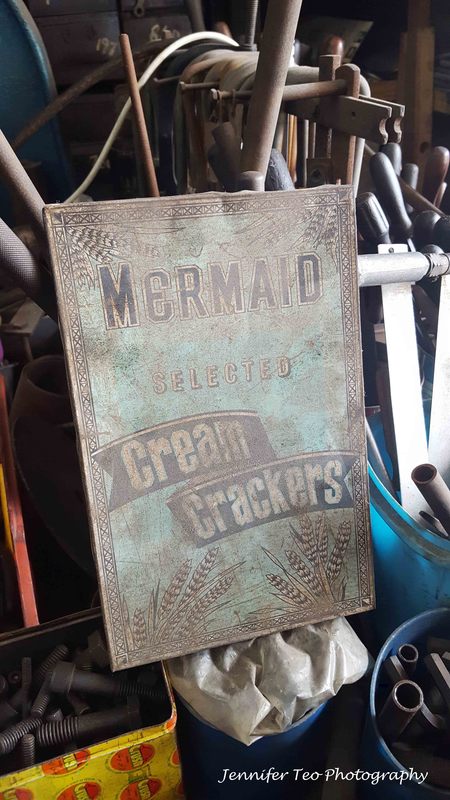

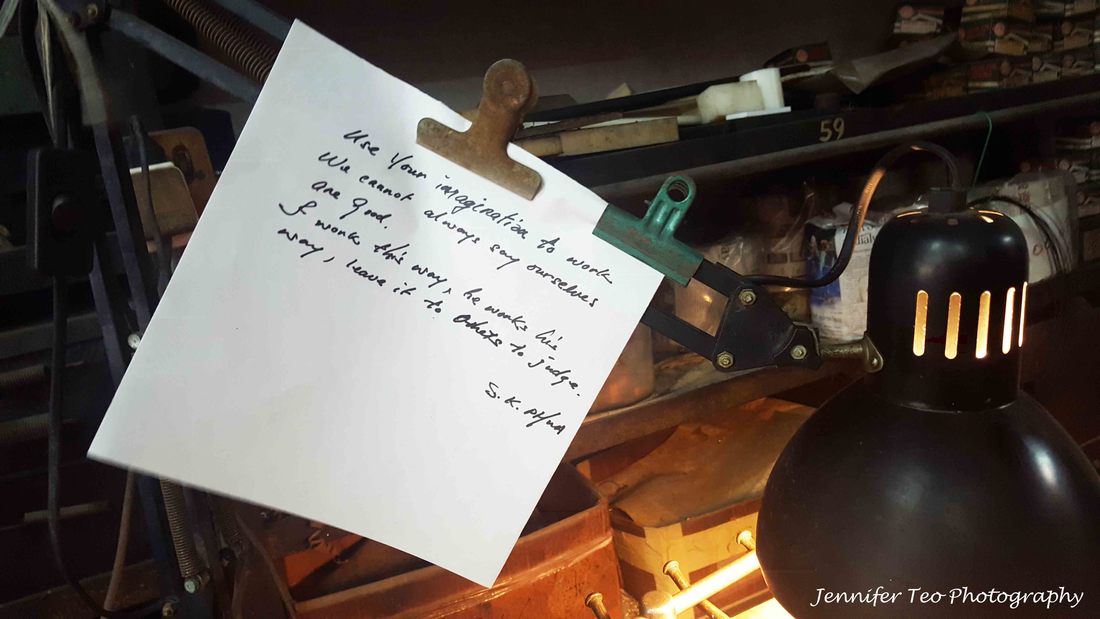

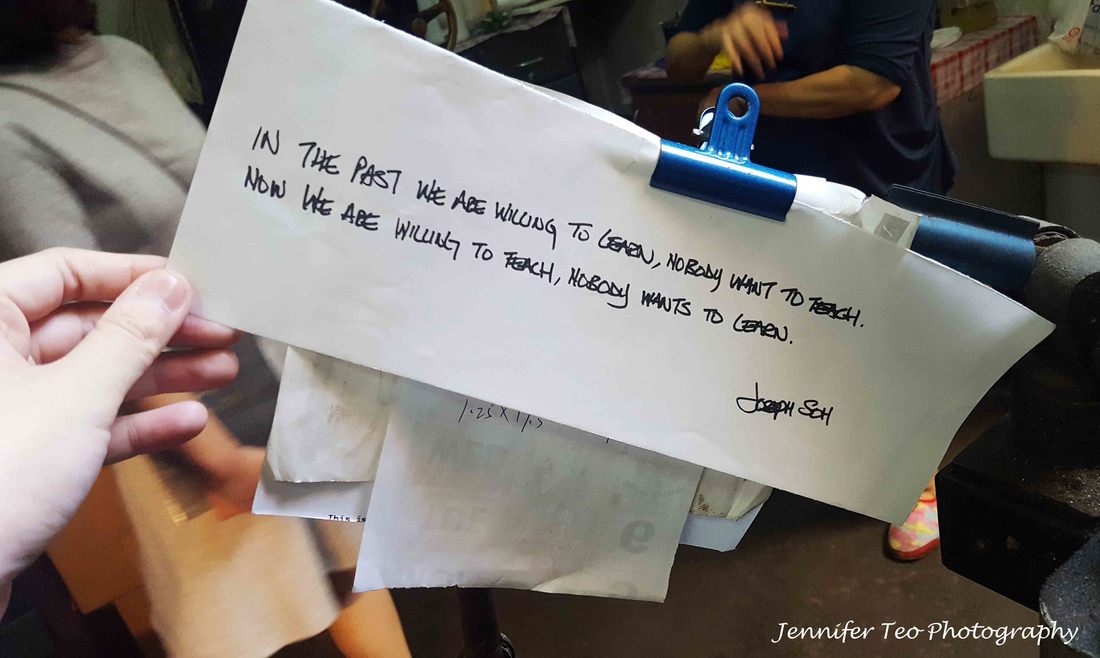

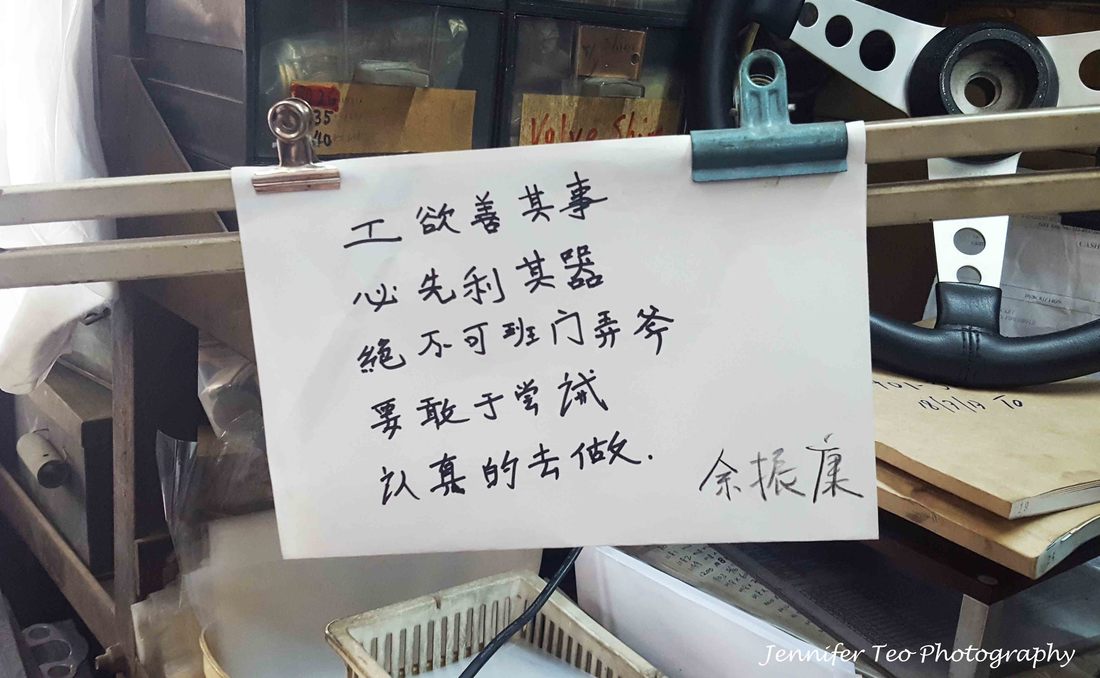

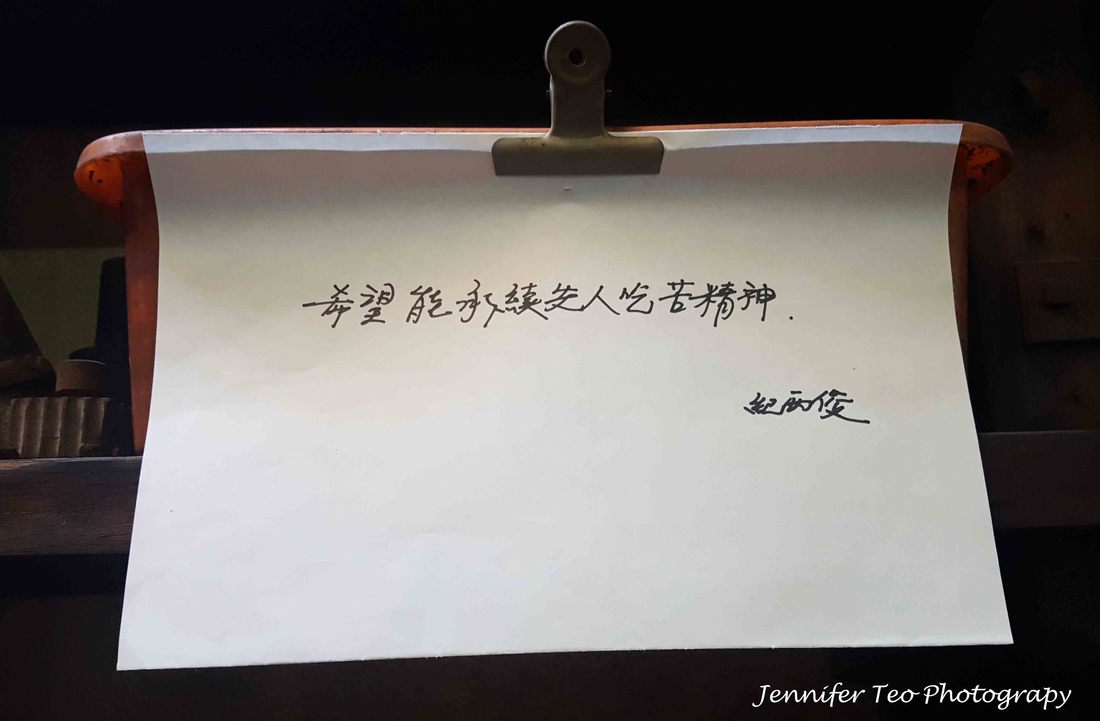

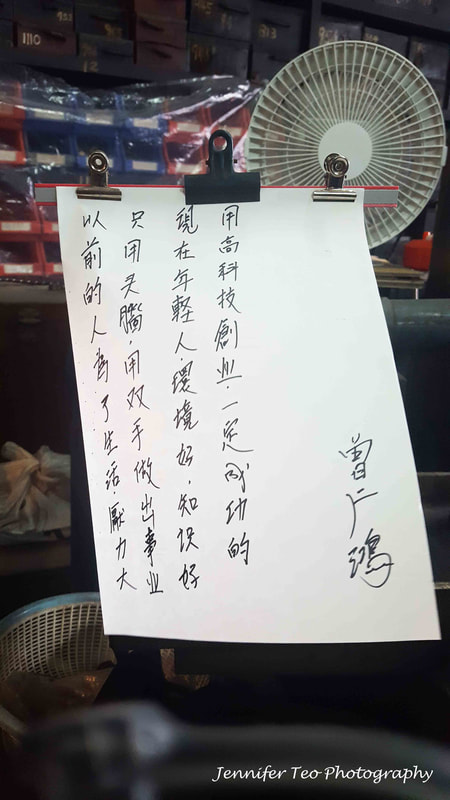

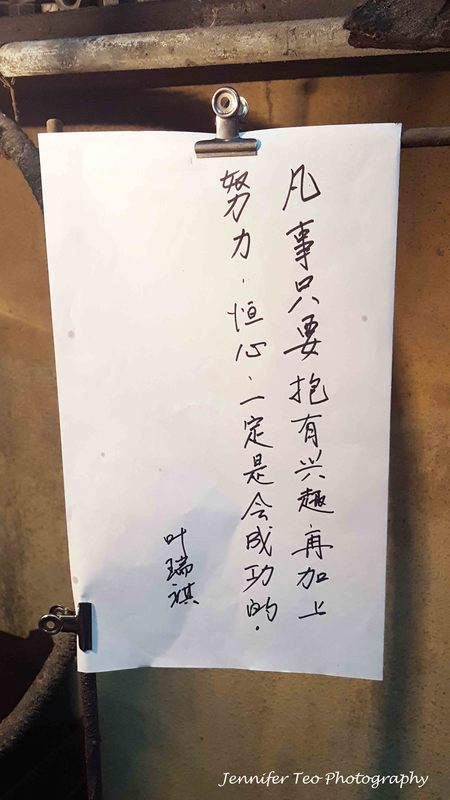

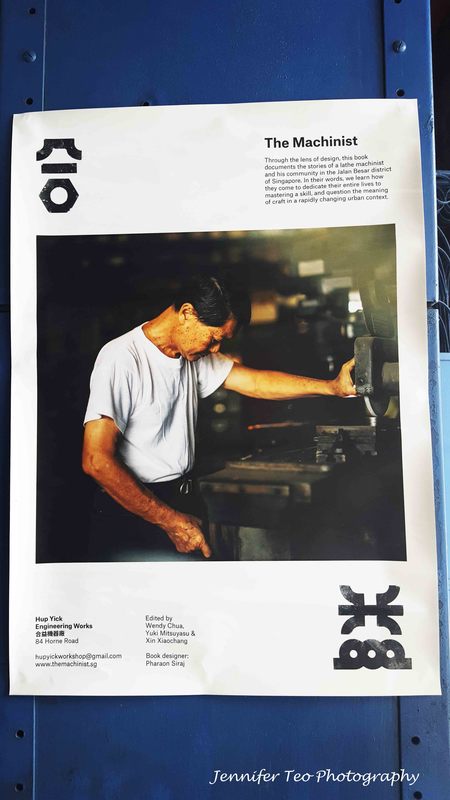

Manual machinists are skilled, dexterous individuals who drill, cut and shape items both manually and with machine tools. Working in industrial shops or plants with blueprints and specifications, machinists produce anything from bed springs to auto parts. Working with exacting precision is a large part of manual machinists' jobs. They are responsible for cutting, slicing, drilling and in some cases repairing the very machines that they work with. Machinists must operate with care at all times. Safety is important when working with steel, glass and metal. Some of their work involves heat-processed or lubricated items as well, and the machines and parts they use can be heavy and dangerous. Manual machinists usually develop skills working with specific equipment, tools and shop machinery while enhancing their manual dexterity on the job. It's sad to say but manual machining is a dying trade. This trade is dying in a big hurry. Cheaper imported tooling and the decline of manufacturing in this country are causing most machine shops to either shift their focus or close down. Jobs are scarce and there's no hope for a reversal either. What few jobs that are left won't last much longer either. The good days are long gone. It was on a walk through Jalan Besar that I spotted this Hup Yick Engineering Pte Ltd hardware shop (exact address is 84 Horne Road) and here I met Mr Yee Chin Hoon, a machinist aged 69 who has been practicing his craft for more than 50 years, since he first worked for his father as an apprentice at 16. Mr Yee is one of the last few manual machinists in Singapore. Mr Yee is hoping that someone is interested on an apprenticeship with him to learn the ropes so that Hup Yick will carry on. But with no takers, it is likely that Mr Yee will retire soon. A book titled "The Machinist" was launched recently by three aspiring designers to commemorate this disappearing skill in Singapore. It has been a while since i last stepped into a workshop like this with ageing interiors. It is a real blast from the past. I could breathe in and to taste the flavour of ages past which is also one of the best joys of time travel. Machines standing next to one another, with grey walls. Such shops have witnessed generations of families plying the same trade passed down from their ancestors. According to Mr Yee, these lacquered biscuit tins are stacked high on the shelves and they are labelled according to car models. The greased containers, lined with newspapers, hold thousands of spare parts for various cars. They were like archaeological time capsules covered in a patina of rust-green. According to the Machinist book, Mr Yee helms the second-generation metal lathe workshop and will be the last in his family to continue the industrial craft. Hup Yick Engineering is a manufacturer of auto-parts for the after-sales market of imported sales, running the gamut from the Morris Minor and Austin A50 of the Sixties, to the Toyota and Nissan of the Eighties. Cars in the past were driven for a longer period and the worn out parts needed constant maintenance. In his small way, the auto parts machinist contributed to the national development. Adapted from the Machinist book, Mr Yee trusted the machine to do its work but listened intently to its breath. He would repeatedly experiment with the different variables until he found the best composition. He lightly clamped the brass rod between the anvil and spindle of his micrometer to gauge the diameter and then turned the dial to the precise environment. These methodical steps have been ingrained in the memory of his hands as he moved with a musical rhythm. It was so fascinating to watch. The preparation of tooling is a process that cultivates a deep well of patience. Though Mr Yee has reached the age of retirement, and as much as he denies it, he enjoys this job too much to let it go. He finds it unbearable to imagine that all the toolings and moulds, the obsolete auto parts and the ready stock, the machines and the raw materials would be rendered worthless scrap metal should the workshop be sold one day. Everyday, he is filled with a deep sense of poignancy as the last to hold the baton but with no one to pass it on. Three young designers in the above photo (standing from left with Mr Yee and his daughter on the right) namely Wendy Chua, Xin Xiaochang and Yuki Mitsuyasu, are so impressed with Mr Yee's skills and commissioned him to use his specialised metalwork equipment to create artisanal products such as jewellery, chess sets and vases etc. They are also the authors of The Machinist book, largely dedicated to the life and times of Mr Yee. A You Tube video of the machinist produced by one of the authors, Wendy Chua on Mr Yee's lifetime dedication to the metal lathe craft. I said goodbye to Mr Yee and he handed me one of his business cards. It’s designed in a simple traditional style, one he says he won’t be printing any more business cards. It’s not just the machines that we're losing, it’s the people who hold the knowledge of the craft who are disappearing, too.

It is my hope that the machinist does not become another lost Singaporean heritage. Let us acknowledge the importance of skill in industries, and start giving the skilled worker their dues, not only in terms of decent remuneration but also social recognition. Otherwise, we are facing an era of industries with machines without skilled people to run them. Training alone does not build skill. It needs dedication and hardwork from the workman to build his skill, and this needs motivation for the person to do so.

2 Comments

29/10/2022 10:57:17 pm

EQuran School is the leading Online Quran Learning Academy which provides online Quran tutors at home, Online Quran learning for kids, Online Quran reading & Quran classes for kids, Online Quran institute, Best Islamic School

Reply

30/10/2022 02:54:11 am

They are responsible for cutting, slicing, drilling and in some cases repairing the very machines that they work with. Machinists must operate with care at all times. I’m so thankful for your helpful post!

Reply

Leave a Reply. |

Author

|

RSS Feed

RSS Feed